Configure to Order

Configuring equipment order services overseas means a larger share of capital is tied up in finished goods inventory that fills a long supply chain, and it leaves you less responsive to shifts in demand. Postponement gives you the greatest flexibility in your supply chain.

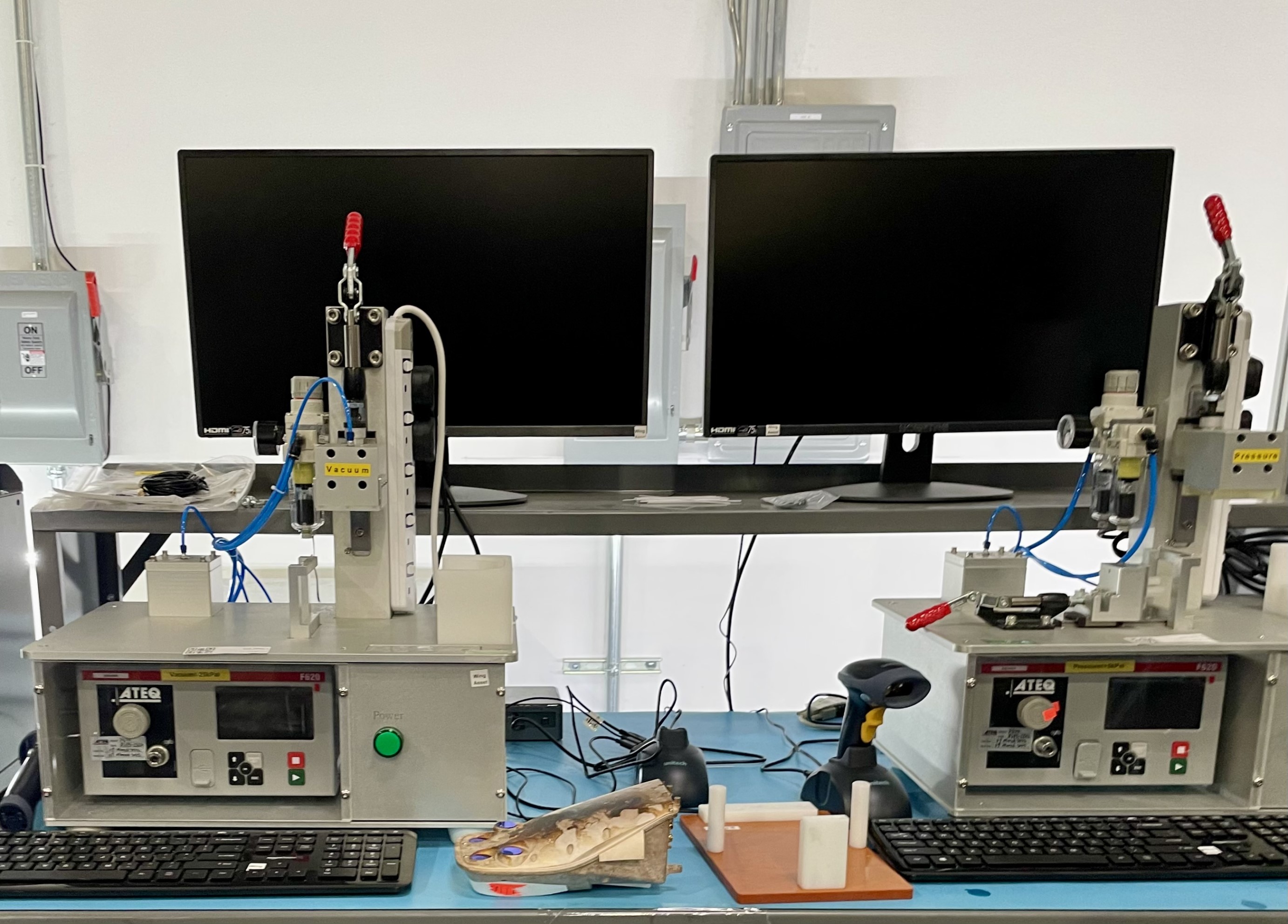

SMS will partner with you to develop, configure and deploy a hardware, software and a wide variety of application services. We configure and deploy equipment to ensure smooth plug and play when the systems are delivered. Final configuration in the USA in proximity to your customer provides certainty and no loss of time.

- Pre-configured & multi-vendor solutions.

- Quick configuration and preparation of different versions of the same product

- Installation, testing, and programming of various equipment

- Various levels of board and component integration

- Staging and Configuration (build the required configuration including cabling, cards, modules, pluggables, software, firmware, racks).

- Clean Room – Ability to develop value add solutions requiring the handling and processing of sensitive electronic, medical or communications equipment orders in a new clean room environment.

- Software downloading and/or firmware updating

- Test and pack

Assemble to Order

We offer consigned and turnkey production assembly services from small to large sized production order, performed locally in Texas, USA. While we are cost competitive, we deliver only the highest quality products to our customers. We also handle any custom cables, packaging and contents that go along in the final packaging. We can ship a fully functional product directly to your distribution center or end customer if required.

- Build to order & Final Assembly: Contract Assembly Service for smart devices and equipment with first class manufacture setting.

- Direct communication with specialists of different functional fields

- Consolidated shipments and pre-scheduled deliveries

- Individual packaging solutions for extra-secure deliveries

- Product assembly analysis and improvement recommendations

- Quick product modification and repairs

- Re-engineering

SC Management & Material Procurement

This solution allows us to store and manage basic level inventory, postponing final customer configuration until the point of demand. These services can include basic custom packaging or complex light manufacturing requiring significant modifications to the base product.

- Components and material delivery time reduction

- Bill of Materials (BOM) optimization via consolidated procurement and suppliers

- Supplier reliability evaluation and control

- Alternative component selection

- Component obsolescence management