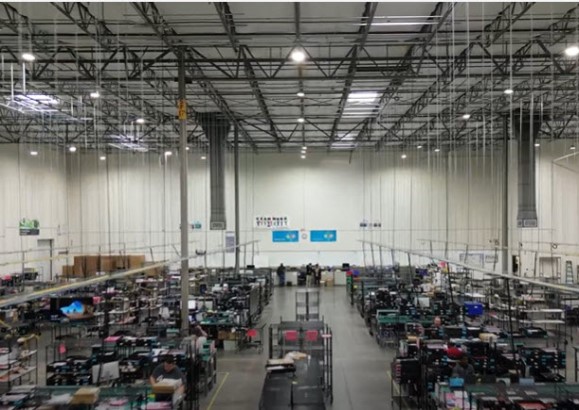

Brand Device Service Depot

Our vast experience handling Depot Services for leading edge technology brands benefits you with the best customer experience, cost, quickest turn around. Providing you with end to end solution for all your customers needs.

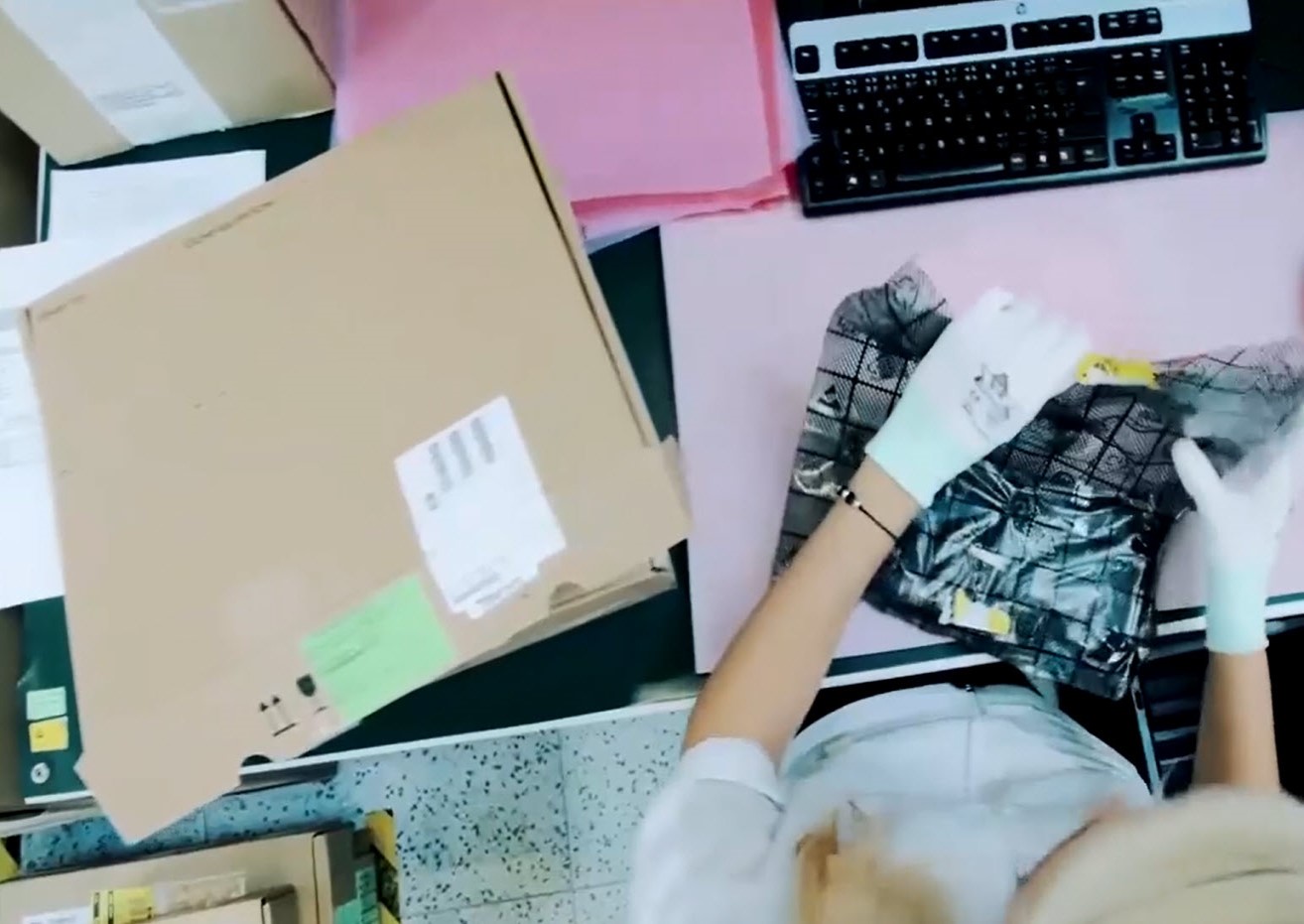

RMA Processing, Triage, Refurbishment and QC Testing

We return electronic devices to their original specifications.

- Computing & CE Devices

- Enterprise Equipment

- Networking & 5G Devices

- CE, IoT & Connected Living Devices

- Personal Health Care & Medical

Return Device Logistics & Repair Management

- Manage the return device flow – track/trace/transport/test/triage

- Repair planning, execution & activity reporting

- Inventory Management

- 360 customer information & device history

All in One Solutions

We offer electronics repair, innovative test software, as well as customer service support, all from the same place. This eliminates inefficiencies and lets us provide our customers with the best service.

Our all-in-one depot service model enabled by our integrated software solution provides improved KPI outcomes:

- Improved customers satisfaction and retention

- Reduced turnaround and processing time

- Improved accuracy and reliability

- Reduced inventory and logistics cost

In Warranty and Out of Warranty

SMS implements solutions to meet your in and out of warranty service criteria that satisfy your customer. We make the right decisions with a primary focus on customer satisfaction, without neglecting cost efficiency and profitability. We provide a new life for your Out of Warranty products.

Case Management

- Register, manage, track return/repair/warranty cases

- Status, history and end customer of individual devices

- Warranty validity checks

- Turn-key device logistics

- Transparency and current information about the status of the device

Device Swap & Spare Parts Logistics

- Procurement, Warehousing and fulfillment

- Repair of Defective back to warrantee replacement.

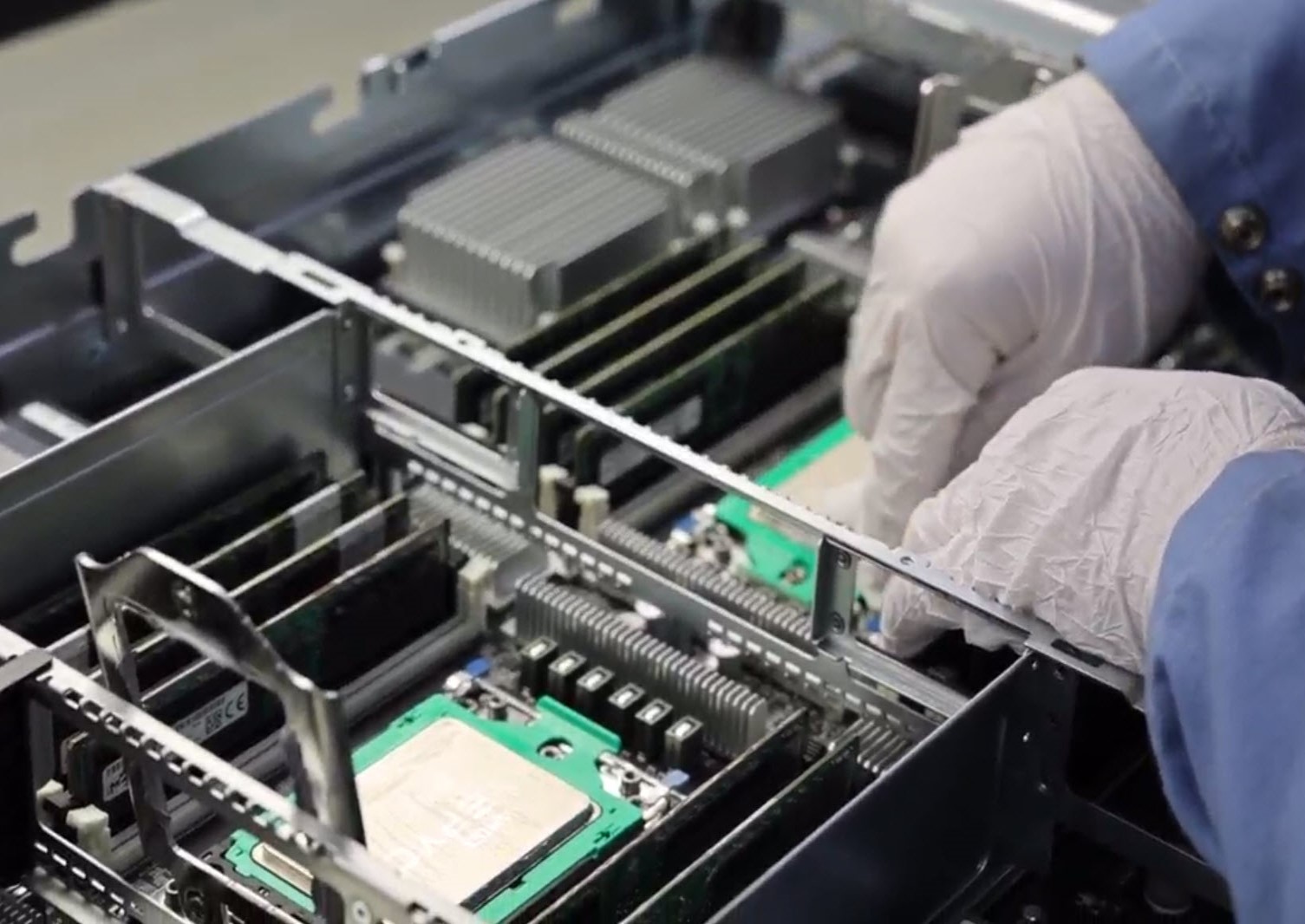

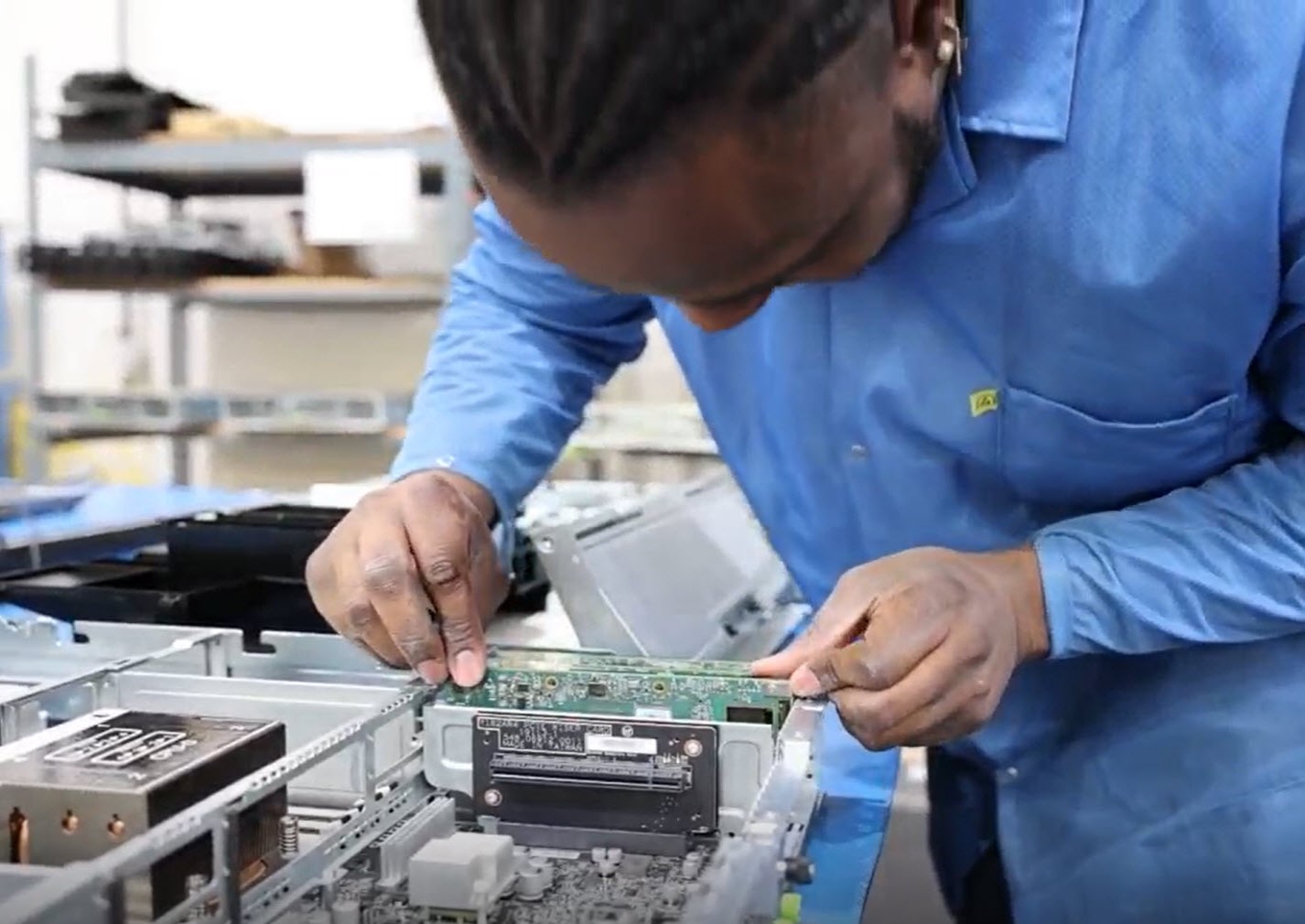

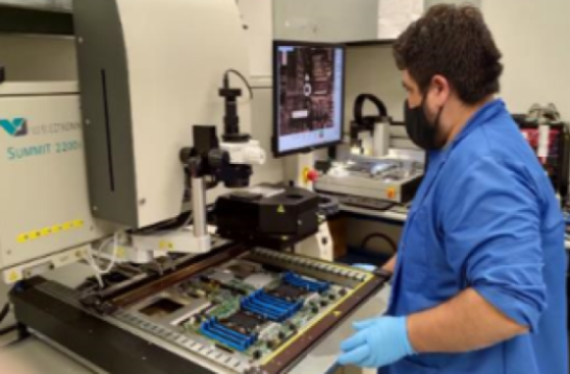

Servers, Switches, and Routers

SMS offers repair solutions for servers, switches, and routers. We provide testing and detailed diagnostics through the repair process to ensure effectiveness. Best in class service for enterprise equipment keep your costs down, increase system up time without interruption.

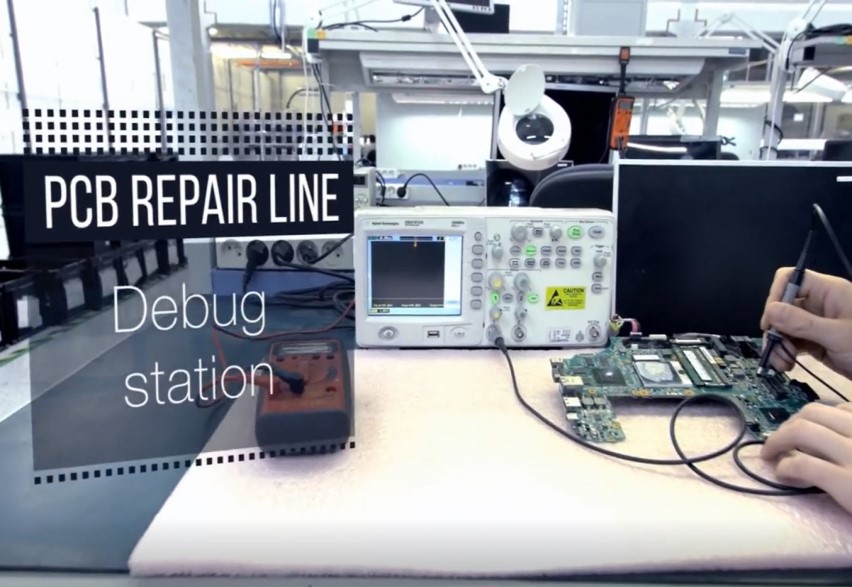

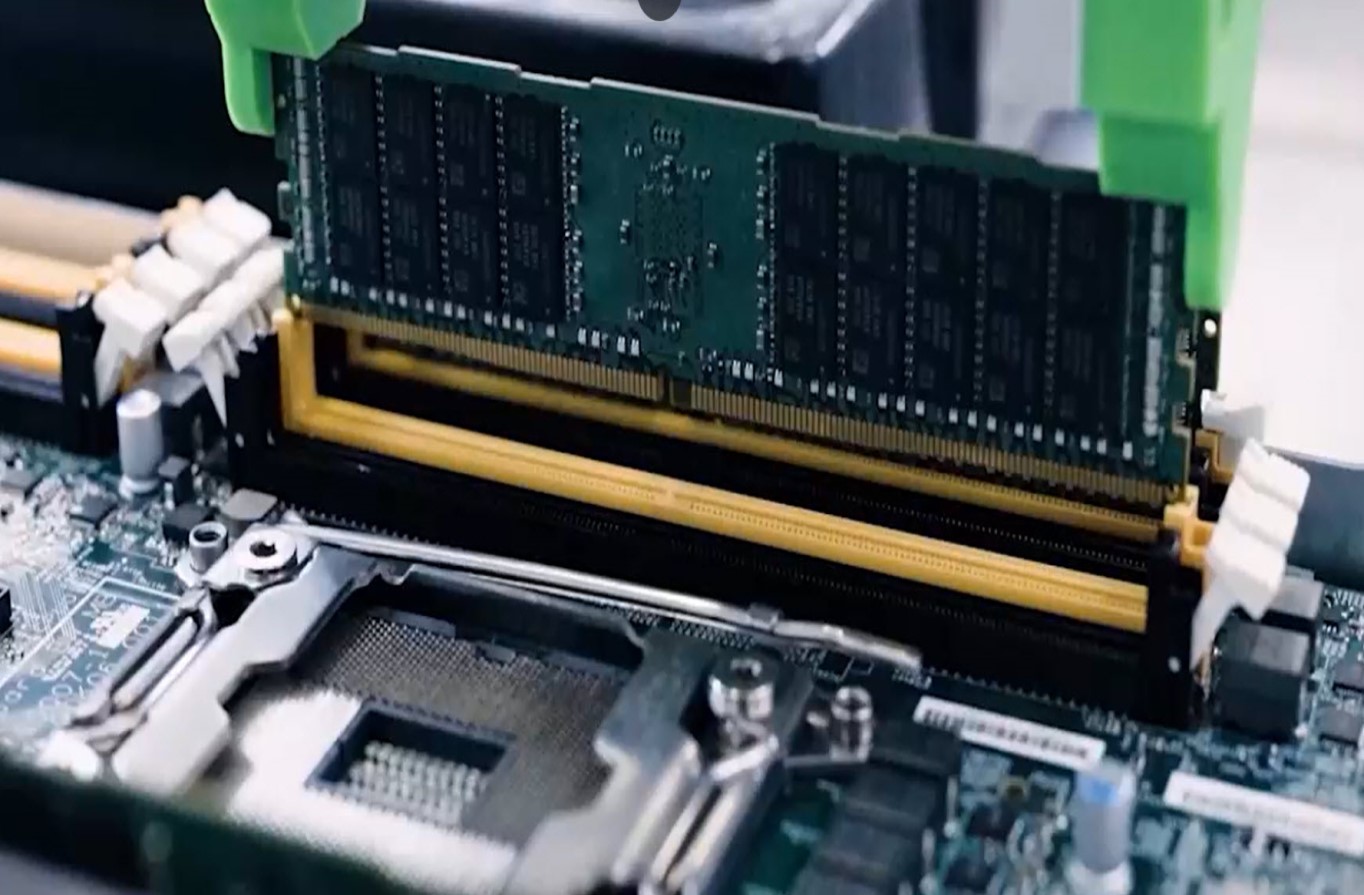

Mother Board Repair

We provide the most advanced mother board repair and provides detailed diagnostics of the technology. Solid state drives, memory, and CPUs are integral parts of the board and we have the technical proficiency to repair and maintain them.

Board Repair Diagnostics

SMS repairs the main logic board, by using advanced diagnostics and detailed analytics down to the chip level. This provides unique insight into any problems the board was experiencing, as well as opportunities for technological advancement.

GPU Repair

Our expert team of technicians has years of experience in repairing GPUs and can quickly diagnose and fix any issues affecting your GPU's performance. Our technicians use only the highest quality parts and tools to ensure that your GPU is repaired to the highest standards.

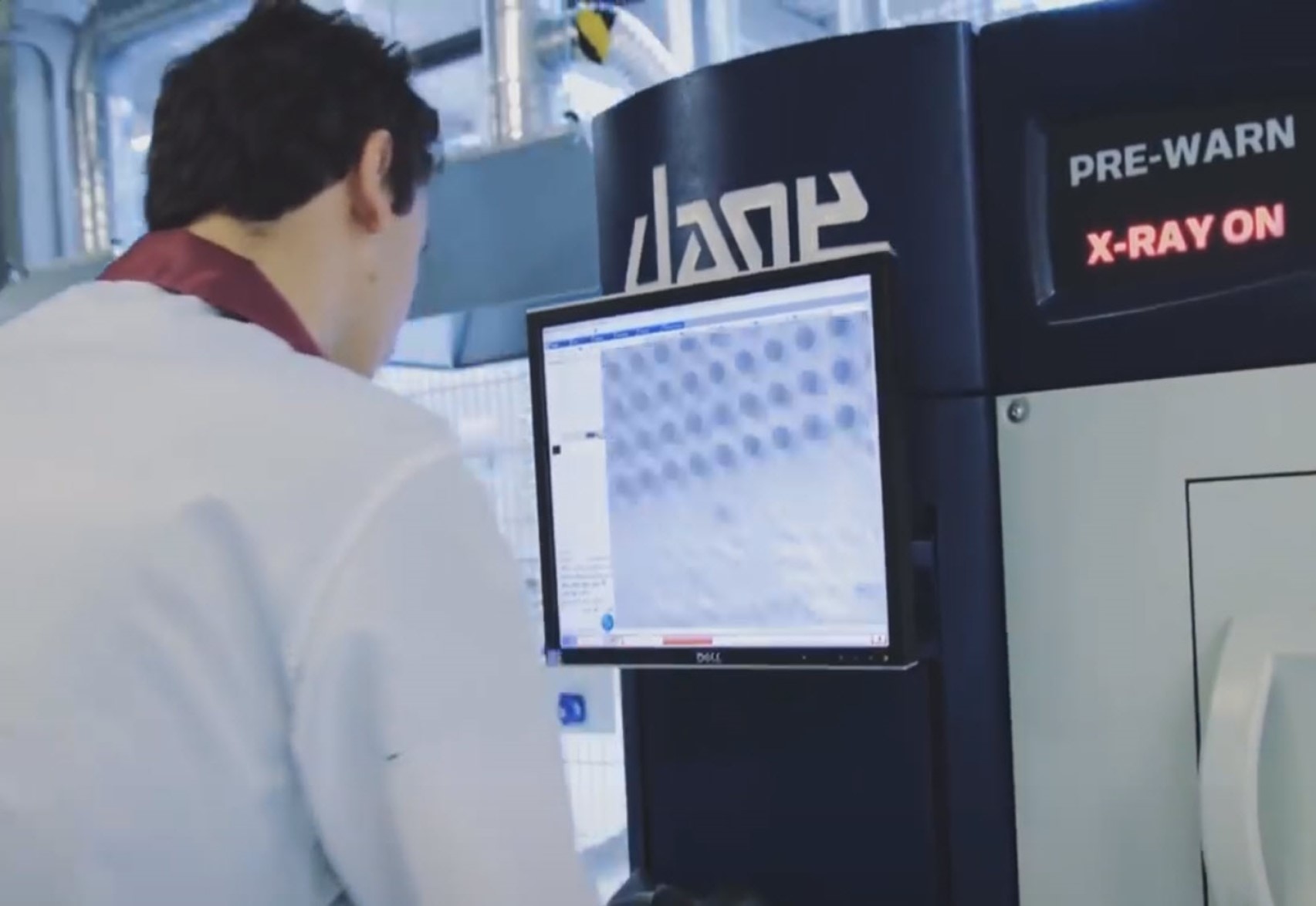

Component level BGA & X-Ray

Our circuit board repairs are performed all the way down to the component level using state-of-the-art diagnostics, inspection, ball grid array (BGA), fine pitch soldering, and x-ray inspection and validation systems.

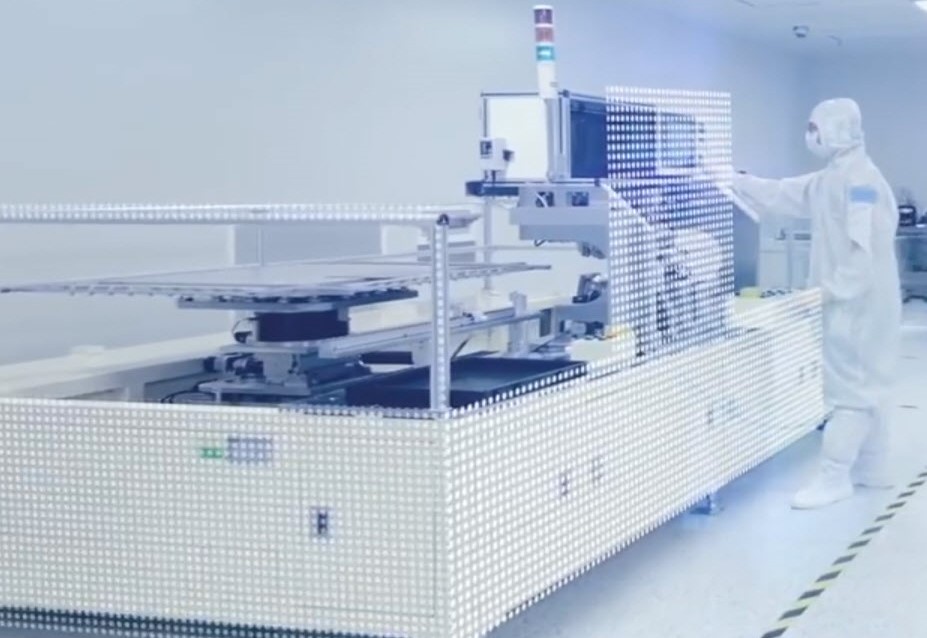

LCD Panel & Touch Screen Display Repair

We perform panel-level LCD repair and touch screen assemblies by utilizing advanced processing equipment and a clean room environment. Our bonding and de-bonding experience has placed our repair capabilities at the forefront of the industry.

Flat Panel Monitor Repair

SMS’s vast experience in LED panel/LCD repair and flat monitor repair mean that you can avoid cost of new purchases. Repairing the LED panel/LCD panel further enhances the savings.

LCD Polishing, Delamination, Repair & Refurbishment

We refurbish and repairing the most technical parts in order to reduce the overall cost of repair for you and your customers. We use the most innovative techniques and test equipment to ensure the highest quality component repair.

Functional Repairs

Our skilled Technicians have years of experience and provide Level 1 to 4 repairs on electronic components. Ball Grid Array (BGA) reworks, display and LCD refurbishment.

Level 0 to Level 4 Electronic Repair

Firmware, Lite Cosmetic Refurbishment, Part Swap, MLB Repair (non-BGA & BGA). All work performed with the highest level of precision and quality. Our process automation and control systems ensure high yield at every level.

L0 DOA, NTF, Accessory replacement

L1 Screen & Clean, SW/FW upgrade

L2 Component or Part replacement, fault find and repair electronic & PCB (basic solder)

L3 Multi-solder point solder & MB replacement.

L4 Debugging, Troubleshooting, BGA, FA.

Innovative Solutions - Custom Service Cells

- Client configured production cells rigorously adapted to your project

- Set up according to your specific process and scope

- Environment & Equipment a la carte

- Consignment or Investment in specialized equipment

Testing & Grading

Our automated testing and grading solutions are flexible and cost effective.

- Test components in standalone or designated test environment

- Grading assessment vs set customer criteria

- Visibility of test & grading results via multiple platforms

- Audit trail for compliance

Engineering Support

Our company is founded on Engineering, and we are continually analyzing workflows, service processes, equipment, new technologies and data management to identify inefficiencies & bottlenecks to deliver a better outcome for your clients.

Electronic Component Upgrade and Remanufacture

We refurbish and repairing the most technical parts in order to reduce the overall cost of repair for you and your customers. We use the most innovative techniques and test equipment to ensure the highest quality component repair.

High Yield Parts Reclamation

SMS reclaims a high percentage of parts and components to reduce your need for replacement parts. We are innovating and creating better ways to test, requalify, and track these components throughout our process to make them available for you.

Clean Room Solutions

SMS has several clean room and environmental control options for our clients designed to minimize the presence of airborne particles, pollutants and contaminants, such as dust, microbes and chemical vapors. Temperature, humidity and air pressure are controlled to maintain optimal conditions for critical processes.

Decontamination

Medical and Healthcare products come with more stringent process controls and regulations. SMS’s IT solutions, Quality Management Systems, and engineering teams to complete the process with the precision and care you would expect from your own team.

Customized Support

Fast Issue Resolution

Data Insights

Unified Knowledge Base

Auto Receiving

Warehouse Order Picking Automation

Test Automation Systems